The delivery of IMRT calculated dose profiles can be achieved in two ways: MLC or fixed / solid beam modifiers. The MLC is known for its authomatic set‐ups. Looking at the total time for dose delivery, the fixed beam modifier technique shows lower total treatment per patient. Similar and different clinical studies has clearly demonstrated that solid beam modifiers are much superior to MLC when resolution of the calculated smooth fluence map is tested. The QA for fixed beam modifiers is less demanding than for MLC. Please study solid beam modifier vs MLC sheet describing these vital parameters.

CNC Block Milling System

XYZ axis automatic CNC machine for filter production. Compete software package (windows). Standard ASCII File Formats. A small compact table model.

• Active cutting area: 300x200mm adjust

• Styrofoam block size: maximum 500x250 mm

• Maximum drilling depth: 90mm

• Cabinet Size: L.: 610mm, W.: 650mm, H.: 715mm Cabinet weight: 102 kg

ACD-4 MK 5 Block Cutting Unit

Small and extremely reliable maintenance free version. Block cutter with touch screen for adjustments. Most modern software version with all clinical software tools. Full dicomRT interface via shared directories or dicom deamon (optional). The system integrates full patient library features facilitating the process of creating filters and mounting them on tray or applicator. All though multi leaf collimators have been introduced, RT departments still opt for automatic cutters for irregular blocks.

• Cutting accuracy: better than 0,5mm

• Cutting speed: 10mm per sec.‐adjust

• Active cutting area: 380x380mm adjust

• Styrofoam block size: maximum 450×440mm Power supply: 240 VAC

• Cabinet size: L.: 72 cm, W.: 38 cm, H.: 72 cm

• Cabinet weight: 30 kg

• Software: full windows version with dicomRT inertface

Meditronix Manual Styrofoam Cutter

‘Medironix’ Manual Styrofoam Cutter is the specialised equipment for the radiation therapy department to cut high consistency block foam mold in CRT. It is easily adjustable to accommodate many source‐to‐tray and source‐to‐film distances. A verification light allow the operator to check the accuracy of each cut before the blocks are cast. Hot wire with a tension‐adjustable organ to ensure that cutting surface. Lowest price in the industry.

▪ Stand alone manually controlled high precision hot wire cutter for photons

▪ Adjustable source‐to‐tray and source‐to‐film distances

▪ Verification light to check the accuracy of each cut before the block is cast

▪ Stainless Steel 304 structure

Specifications:

• Maximum cutting area with one block : 380x380mm

• Maximum distance of source‐to‐film : 1400mm

• Maximum distance of source‐to‐tray : 560mm

• Maximum cutting thickness : 140mm

• System dimensions (LxWxH) : 700x600x2300mm

Meditonix Electron Foam Cutter

This is a low‐cost, counter‐top hot‐wire cutter.

Features:

▪ Table top model

▪ Provides white acrylic top as cutting surface

▪ The unit has an easily replaceable Nic‐Chrome cutting wire

Imported Blue Styrofoam for Photons & Electrons

High density 40 PSI dow® Styrofoam is designed to provide a flat surface essential to the shielding block pouring process. Expressly tailored to offer dimensional uniformality and very high density. Available in a complete range of dimensions and thickness for photons and electrons. For photons 12’’x12’’x3’’ pack of 30 foams For electrons 12’’x12’’x3⁄4’’ pack of 30 foams

Styrofoam Blocks

(For electrons 12’’x12’’x3⁄4’’)

Styrofoam Blocks

(For photons 12’’x12’’x3’’)

Alloy Melter

Highly durable melter with heavy gauge stainless steel 304 inner and outer walls. Full trap ceramic heaters, temperature control and internal heater fitted ball valve dispenser to avoid solidification of alloy inside tap.

Low & Medium Melt Alloy

Low melt (70°C) or medium melt (95°C) cadmium free alloy. Available in kilograms.

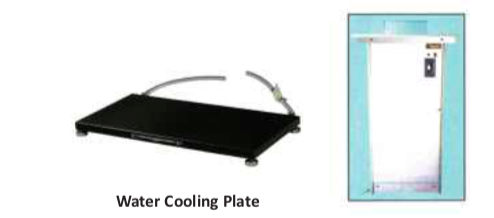

Alloy Colling Plates

Alloy cooling plates are available in two variants. 2x1ft. Water cooling plate and compressor based refrigerated cooling system.

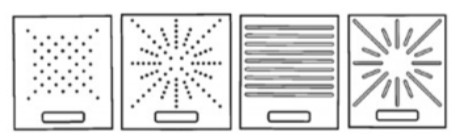

Shielding trays

Available with standard or custom hole and slot pattern in polycarbonate or acrylic for any brand of linac or cobalt.

Block Compressor & Electron Molds

Sturdy metallic made block compressor for holding electron and photon foams, while pouring alloy. Electron molds in 5, 10, 15, 20, 25cm field sizes made of specially formulated high temperature with‐standing polymer silicon rubber.

Tools & Accessories

Stainless steel mug for pouring alloy, drill machine with drill bits, digital thermometer, wrench, coarse file, soldering iron, hammer, screw driver, nuts and bolts etc.

Block Casting System

▪ Designed to provide clean working conditions during block casting

▪ 4’W x 2’6”D x 6’H; wooden structure with mica finish

▪ Stainless Steel 304 work surface

▪ Electric Vent Hood for absorbing

fumes and heat

▪ HEPA & Charcoal filter assembly

fitted

▪ Fluorescent light inside

chamber

▪ Cabinet below work surface

▪ 10 feet exhaust pipe standard,

additional length available

Work Station

▪ Designed to provide good working conditions during block making

▪ 4’W x 2’6”D x 6’H; wooden structure with mica finish

▪ Stainless Steel 304 work surface

▪ Heavy Duty Drill Press and Vacuum Cleaner fitted

▪ Fluorescent light inside chamber

▪ Cabinet below work surface

Tray Storage Cabinet

▪ Constructedof sturdy wood with mica finish

▪ Aluninium side rails to

hold shielding trays

▪ Lockable caster wheels

▪ Side handles to move the

cabinet

▪ Custom designed for

required number of tray slots

Block Verification Unit

Offers quick and precise method for checking tray mounted shielding blocks. It features a high intensity tungsten light source with fine X, Y adjustments. Linear bearing carriage for smooth motion and precision distance indicator to tray and film.

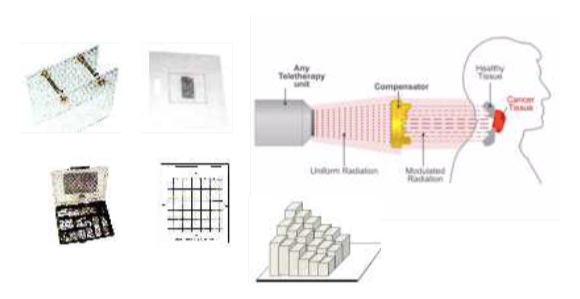

Manual Tissue Compensator

Adjustable zig made of acrylic sheets and brass rods. Acrylic sheets of 33 x 33 cm x 5 mm (custom sizes available). Compensator pieces ‐ made of aluminium of 9x9 mm and various thickness : 2, 3, 5, 8, 10, 15, 20, 25, 30, 35, 40mm, storage box, adhesive, grid charts.